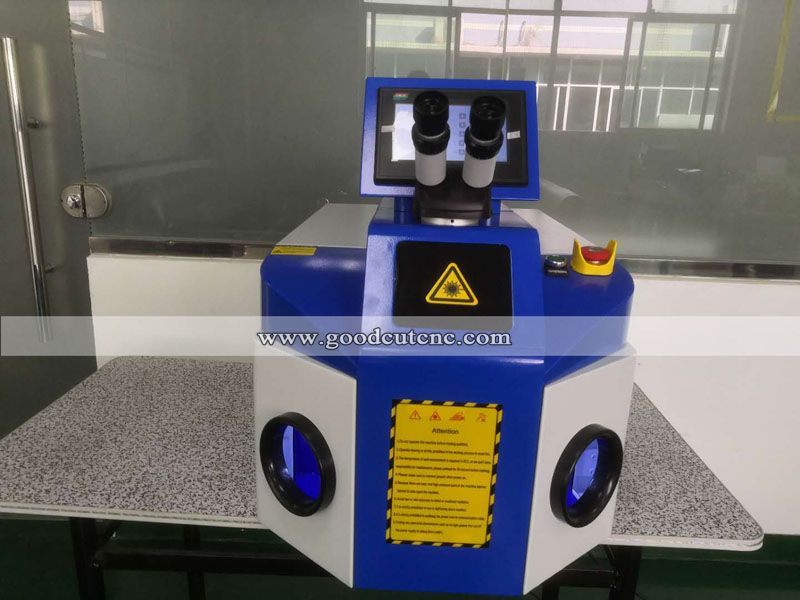

What is a Jewelry Laser Welder?

The jewelry laser welder makes use of a laser beam welding technique. It utilizes a concentrated, amplified beam of a particular wavelength that welds the solid within a matter of seconds. Essentially, the beam acts as a concentrated heat source and provides deep and narrow welds at high welding rates. Due to the laser welding machine price, the machine was considered a luxury item for jewelry stores around a decade back. However, now the laser machine for jewelry has become a staple and necessity for jewelers to own.

How Does the Jewelry Laser Welder Work?

The operator controls the beam generated from the jewelry laser welder, which might be encapsulated by the uniquely designed pure plastic and have CCD (charge-coupled device) monitoring. It works in a much comparable fashion to soldering machines. Apart from this, the machine is not difficult to use. Consequently, any bench jeweler with minimal experience could learn to use it easily with 10 to 12 hours of hands-on experience.

The laser sends out a focused beam on the area that needs to be melted for repairs or redesign. The benefit laser technology has over soldering or brazing is that heat is applied on a minimal area called the bombardment zone. The metal in the adjacent areas does not become molten or injured. The heated laser beams also eliminate any impurities during the welding process. It removes the need for any steps taken after welding with a solder (post-weld treatment). Namely, these steps are cleaning, coating, and pickling. The laser also does not discolor the surface. Moreover, laser welding also adds up to make the metal more robust than soldering and other methods.

What Kind of Jewelry Metals Can Be Welded with A Jewelry Laser Welder?

A jewelry laser welder can work with a wide variety of materials used in the jewelry industry. This flexibility adds up to the applications of the machine, making it more versatile and efficient than standard welding methodologies used in the industry. Metals and alloys that can be worked with using a jewelry laser welder include gold, silver, titanium, stainless steel, platinum, and alloys.

Gemstones, even soft ones such as opals, emeralds, and pearls, would not be needed to be moved during the welding process due to the precision of the laser. Laser technology only finds it troublesome when working with titanium alloys due to how brittle they are.

Applications of a Jewelry Laser Welder

Now that we know what a jewelry laser welder is and how it works. Next, we have to look into the applications it has in the industry. As mentioned earlier, the jewelry laser welder has impacted the jewelry industry and made processes more manageable and efficient. It is what contributed to the large-scale success and application of the machine. Notable uses of the jewelry laser welder are:

1. Used in Resizing Rings: The ring can be resized to a somewhat smaller or larger size. People face this issue when the ring doesn’t fit. Hopefully, instead of buying a new one, they can get it resized at any jewelry store outlet that uses a jewelry laser welder.

2. Re-Tipping Prongs and Repairing Bezel Settings: Prongs can get loose and often lose tips that grab onto the gemstone in a ring. If not tended to, the gemstone can fall off. Fortunately, a jewelry laser welder can precisely pinpoint where the issue is in the prongs and help them hold tight on to the gemstone. It can also work to help fix the bezel settings of the ring.

3. Reassembly of Broken Jewelry: Necklaces, bracelets, and earrings, amongst other small jewelry, can be easily repaired and reassembled using a jewelry laser welder.

4. Repairing Miscellaneous Jewelry: Costume jewelry, and other accessory articles such as eyeglass frames and watch bands, can also be fixed with the help of a jewelry laser welder.

5. Porosity Fix: Porosity refers to empty spaces left in a metal or material, making it porous and, as a result, weak. Porosity can easily be fixed and tended to use a jewelry laser welder, giving the material its strength and making it dense.

6. Custom Designs: Custom designs, or made-to-order designs, are possible with ease thanks to jewelry laser welder technology. That is because it helps the jeweler redesign and modifies the jewelry in many ways to allow it to fit the customer’s requirements.

Contact: Smile Ji

Wechat: 008618396857273

Whatsapp: 008618396857273

Tel: 008618396857273

Email: smileji@goodcutcnc.com

Add: 402 Jinxing Longsheng Building, High-tech district, Jinan City, Shandong Province, China