GC-WJ Jewelry Fiber Laser Welding Machine with 200w Laser Power

Parameter:

|

Item |

Parameter |

|

Laser source |

Nd3+: YAG |

|

Max. Laser Power |

240w |

|

Single-pulse energy |

90J |

|

Pulse Width |

0.1-20ms |

|

Wavelength |

1064nn |

|

Frequency range |

0-50Hz |

|

Welding pool diameter |

0.3-1mm |

|

Facula diameter |

0.1-3mm |

|

Observing system |

Microscope |

|

Chamber illumination |

LED lamps |

|

Shield gas supply |

One Line |

|

Cooling |

Water cooling |

|

Power consumption |

5.5kw |

|

Power supply of laser |

220V /50HZ |

|

Power supply of chiller |

220V/50HZ, 1HP |

|

Running environment |

5℃-30℃ 5%-75% humidity |

|

Net weight |

110kg(welder)+50kg(chiller) within |

Feature:

Application:

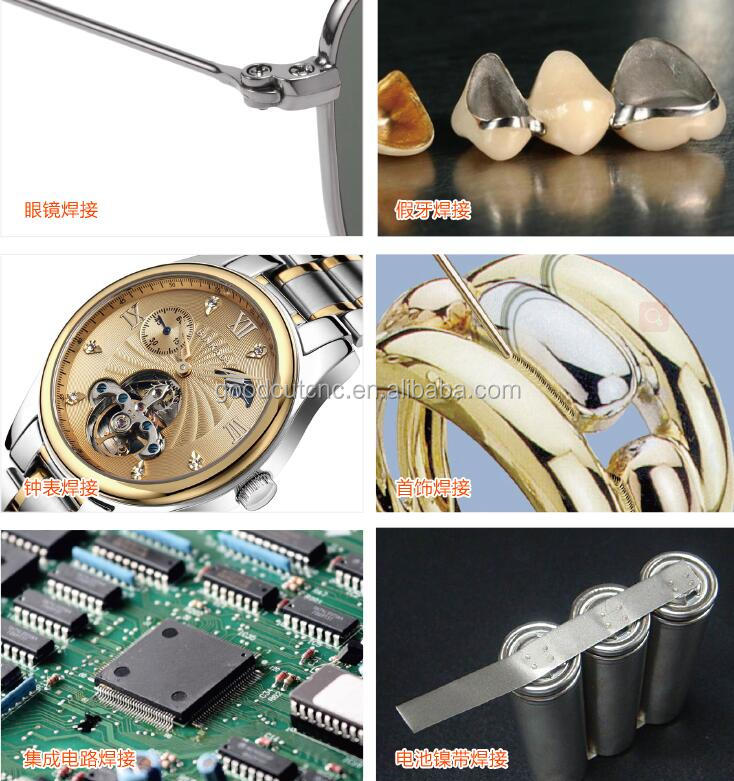

Widely used in precision casting welding, such as:

jewelry, dentures, clocks and watches, medical, instrumentation, electronics, mechanical mold processing, automobiles and other industries.

It is especially suitable for the welding of gold and silver jewelry's repair holes, spot welding sand holes, repair seam patterns, inlaid parts and claw feet.

Contact: Smile Ji

Wechat: 008618396857273

Whatsapp: 008618396857273

Tel: 008618396857273

Email: smileji@goodcutcnc.com

Add: 402 Jinxing Longsheng Building, High-tech district, Jinan City, Shandong Province, China